Filter leaves cleaning

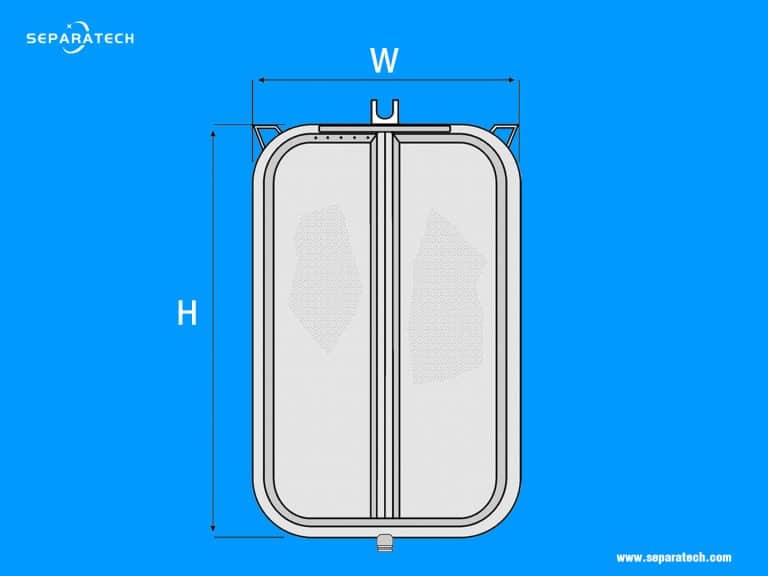

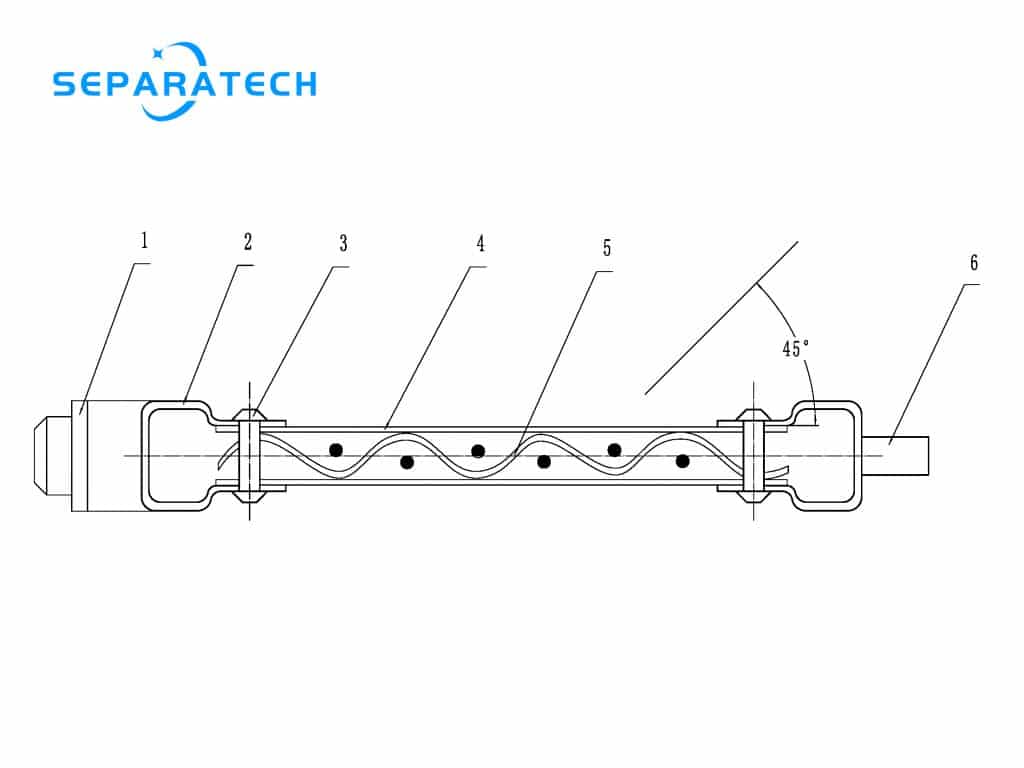

When the working time of the pressure leaf filter is very short and the pressure rises quickly, it is often caused by the clogging of the filter screen. At this time, the leaf filter leaves should be checked, and the filter leaves should be placed in a bright place and observed at a 45-degree angle to the filter plate. If any blockage is found, it should be cleaned in time. The following methods are recommended for cleaning the filter leaf.

Chemical cleaning

The filter plate is cleaned in a clean pool. The cleaning solution is 10-15% NaOH solution (or a cleaning solution that has no corrosive effect on the filter), the temperature is 50-60 °C, and the cleaning time is generally not more than 3 hours. Be careful not to Wash with hydrochloric acid or detergent that generates free ions, as it will seriously corrode the filter.

Mechanical cleaning

Use 6-8MPa high-pressure water to spray and wash, put the filter plate vertically on the wooden board, the discharge of the filter plate is downward, and the nozzle of the high-pressure water is sprayed at a 45 angle to the plane of the filter plate.

The cleaning of the filter leaves can also be washed with steam of 0.3-0.5MPa. The operation method is the same as that of high-pressure water spray washing, and it can also achieve good results.

Pay special attention to the filter plate and never wash the filter in reverse flow, which will make the filter swell, or even tear the filter, and it is easy to scratch the filter.

Pressure leaf filter maintenance

1 Before each shift, check whether the hydraulic cylinder, locking ring, and pull-out head mechanism can move freely, and there should be no jamming or biting. When sealing the filter tank, the locking ring must be completely locked (the pressure of the main oil circuit should reach 5-8MPa), and the handle position on the hydraulic station can be turned from the closed state of the cover to the stopped state to keep the tank cover. Good sealing with the joint surface of the tank. The main gasket between the tank cover and the tank body is a lip seal, and it is necessary to ensure that there is no sundries in the lip during each locking.

2 If the filter screen is accidentally damaged during the cleaning process, silver brazing can be used for repair welding, and it can still be used.

3 According to the usage, every time the filter screen is cleaned, the “O” ring at the lower part of the filter screen plate should be checked once, and if any damage is found, it should be replaced in time.

4 The filter of the vibrator and the prepared lubricator should be refueled once a month to ensure the normal operation and lubrication of the vibrator.

5 Hydraulic cylinder, the movable part of the roller mechanism should be lubricated. The piston part of the hydraulic cylinder should be protected to avoid dust particles, impurities, etc.

6 If the filter is shut down for a long time, the whole unit should be cleaned to prevent the material from being mildewed and corroding the internal parts of the filter, especially the filter plate should be carefully cared for.