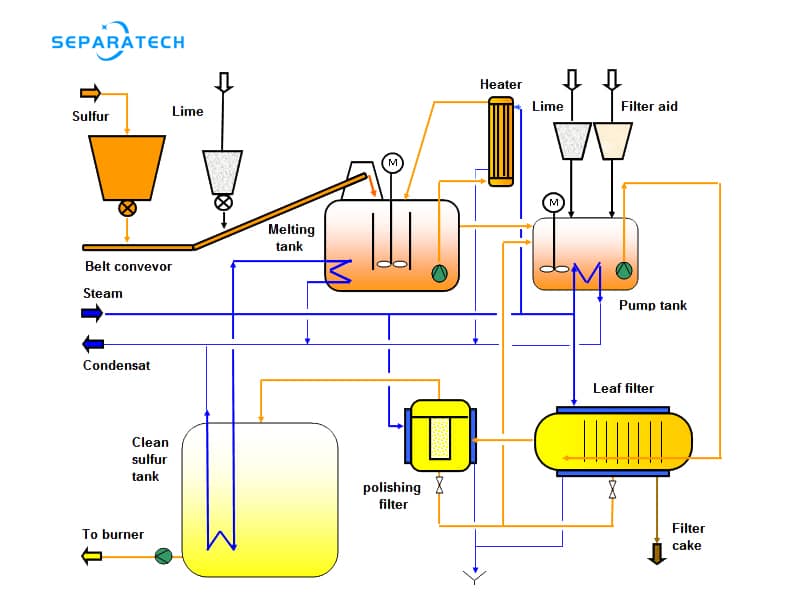

Process Flow

Typical Molten Sulfur Filtration Process Flow of converting elemental sulfur to sulfuric acid begins with the burning of the sulfur to form SO2 gas. The SO2 is recovered and converted by catalyst step-wise from SO2 to H2SO4. Molten Sulfur Filter is one of the critical equipment in process line.

Challenge

While manufacturing Sulphuric Acid from elemental Sulphur through acid manufacturing process as well as Chamber & contact, Sulphur is burned at high temperature and leaves a residue called Sulphur Di-oxide. During storage and handling processing, sulfur becomes contaminated with solids such as dirt and ash. This contamination quickly plugs sulfur burners, SO2 gas filters and catalyst beds. Furthermore, presence of solid matter or ash can create high problem in acid plant. Here Molten Sulfur Filtration with Pressure Leaf Filters find their usage. Basic purpose behind using these is to remove all those particles that can create problem in Sulphur production.

Solution

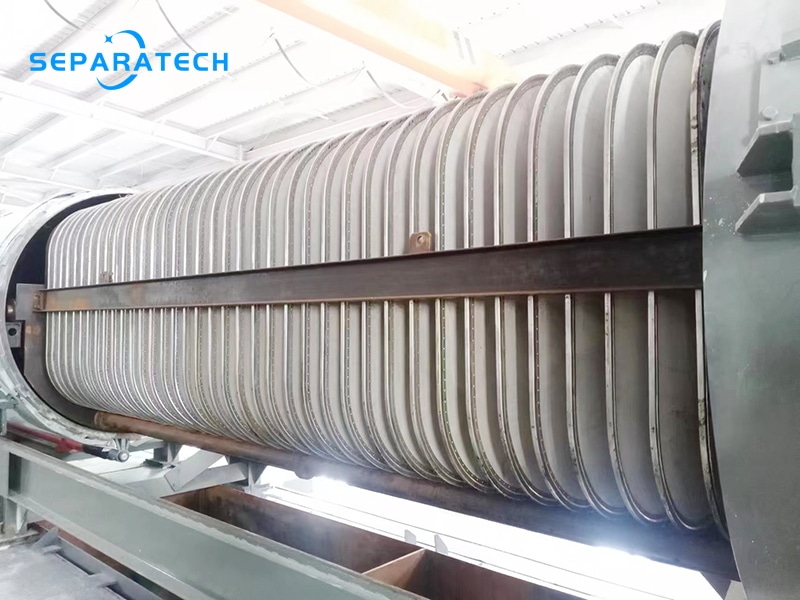

Special designed pressure leaf filters greatly reduce the maintenance costs in molten sulfur processing: burner cleaning is reduced. Shutdowns are minimized and SO2 gas filters can be eliminated. Pressure Leaf Filters Tailored incorporate exclusive features such as a full steam jacket, proprietary filter leaves and devices for eliminating build-up of hardened sulfur.

Characteristic of Molten Sulphur

Molten Sulphur, which is obtained from sulphuric acid has high freezing point and peculiar viscosity, which makes it difficult to handle. When the temperature of molten Sulphur is increased from its melting point (110) to 157oC then its Viscosity heavily decreases and then further increase with the temperature. For having constant temperature of molten Sulphur during filtration process, all the valves & lines and filtration equipment are steam jacketed.

Operating Data

Temperature: 140 – 145 °C

-Flow: 2.5 – 3 Tons / M2 / Day. (Depending upon quality of Sulphur Being Filtered)

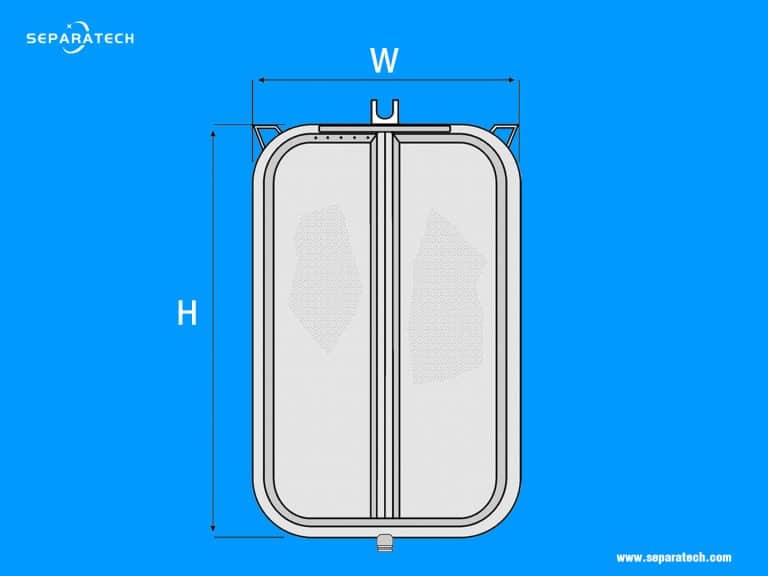

Equipment Type: The Jacketed Horizontal Pressure Leaf Filter

Classification: Retractable shell with a lower support frame

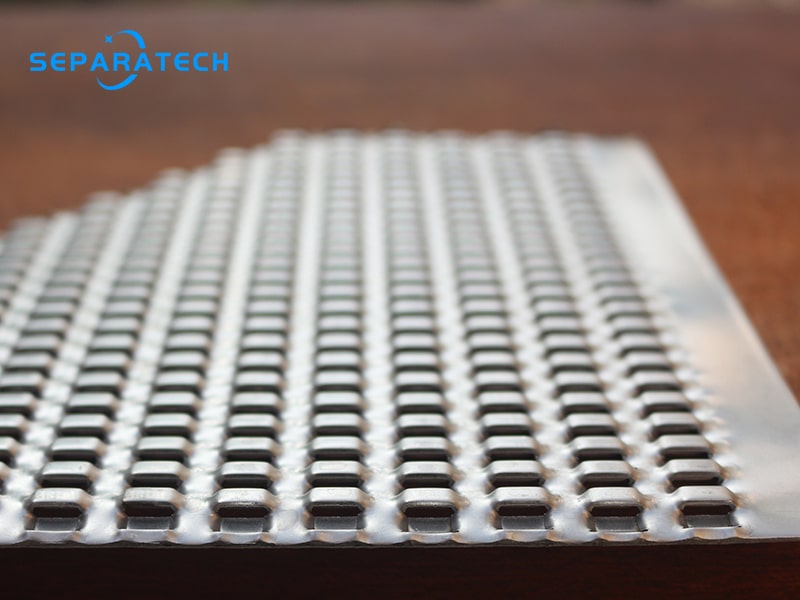

Filtration leaves construction

Good filtration performance begins with high quality filter leaves. We are dedicated to achieve better filtration performance and lower operating and maintenance cost.

5 ply in total

• Custom scale drainage mesh -1

• Custom punched support mesh -2

• 24 x 110 Single Plain Dutch Weave Filter Mesh -2

• Tubular Section, Fork & Nut Bolt, Mesh support mesh Nozzle and Washers

Advantages of pressure leaf filter for Molten Sulfur Filtration Applications

• Decreased maintenance costs and improved plant operation time

• Reduction of contamination reduces the acidity of the Sulphur and corrosion

• Retractable tank and fixed cover; no need to disconnect pipelines for cleaning procedures

• Filter leaves remain stationary; no cake dropping during opening

• Quick closure with long gasket lifetime

• Durable filter leaves with optional acid-resistant filtration mesh

• Fully hydraulic operation

• Tailor-made to your specifications

Expertise

SEPARATECH knows well about molten sulfur filtration. With our sheer motive to manufacture, export and supply an impeccable quality array of Molten Sulphur Filters, we have set up an advanced manufacturing unit. We have improved process performance and eliminated costly maintenance for many sulfuric acid producers. Technologically advanced designs based on over 30 years of experience have made Pressure Leaf Filter from SEPARATECH meet users’ requirements strictly and completely. Available in various models and material of construction as per the application requirements, our Molten Sulphur Filters are manufactured by using high grade material. Suitable for filtering solid matter or ash occurred during the manufacturing process of sulphuric acid, these filters are widely used in sulphuric acid plants.