Leaf filter elements are essential components of pressure leaf filters, which are widely used in various industries for liquid-solid separation. Pressure leaf filters consist of a vertical or horizontal vessel with a number of filter leaves inside. The filter leaves are made of stainless steel or other corrosion-resistant materials and have fine pores that allow the liquid to pass through while retaining the solid particles. The leaf filter elements are arranged in a vertical or horizontal configuration inside a pressure vessel. The vessel is filled with the slurry (the mixture of liquid and solid particles) to be filtered. The pressure inside the vessel forces the liquid to flow through the mesh, leaving behind the solid particles on the surface of the leaf filter elements. The solid particles form a cake that can be removed by backwashing, scraping, or vibrating the leaf filter elements.

Structure of Leaf Filter Elements

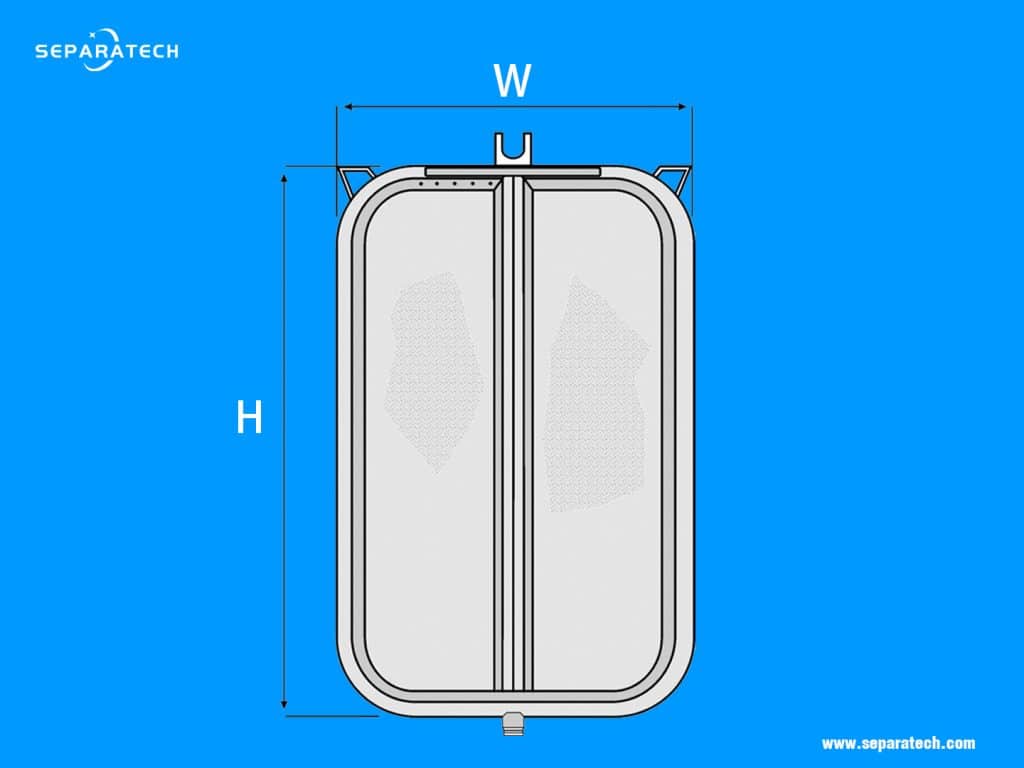

The structure of the pressure leaf filter elements varies depending on the type and application of the pressure leaf filter. However, a typical leaf filter element consists of the following parts:

– A central stem that connects the leaf filter element to the manifold and allows the filtrate to flow out of the vessel.

– A drainage mesh that covers both sides of the stem and provides support for the filter medium.

– A filter medium that covers the drainage mesh and forms the actual filtering surface. The filter medium can be made of woven or non-woven fabrics, metal meshes, or synthetic membranes, depending on the filtration requirements.

– A frame that surrounds the filter medium and provides rigidity and stability to the leaf filter element.

– A gasket that seals the edge of the nozzle and prevents leakage of the filtrate or the slurry.

The leaf filter elements are designed to provide a large filtration area in a compact space, as well as high filtrate clarity and easy cake discharge. Depending on the type of pressure leaf filter, the leaf filter elements can be arranged vertically or horizontally, and can be equipped with cake breakers or vibrators to facilitate cake removal. The leaf filter elements can also be cleaned or replaced periodically to maintain their performance and extend their lifespan.

Why choose SEPARATECH for leaf filter elements?

SEPARATECH is a professional manufacturer and supplier of leaf filter elements for various applications. SEPARATECH has more than 30 years of experience in designing, producing, and installing leaf filter elements for pressure leaf filters. SEPARATECH offers:

– High-quality products: SEPARATECH uses advanced technology and equipment to ensure high-quality standards and customer satisfaction.

– Competitive prices: SEPARATECH offers competitive prices for its products without compromising on quality or service.

– Fast delivery: SEPARATECH has a large inventory of ready-made leaf filter elements that can be shipped within 2-6 weeks after order confirmation.

– Customization service: SEPARATECH can customize leaf filter elements according to customer requirements, such as size, shape, material, pore size, etc.

– Technical support: SEPARATECH provides technical support and guidance for customers before, during, and after sales.

Contact us today to get a free quote and consultation. We will help you find the best solution for your filtration needs.

SEPARATECH has more than 30 years of experience in designing and manufacturing pressure leaf filters and leaf filter elements for various applications. SEPARATECH can provide tailor-made solutions for customers who need high-quality and reliable leaf filter elements for their filtration needs. SEPARATECH’s leaf filter elements are compatible with most brands of pressure leaf filters, including Versis vertical pressure leaf filter, and can meet or exceed the original specifications.

SEPARATECH is your trusted partner for leaf filter elements. Order now and enjoy the benefits of our products and services.

Alternatives of Versis leaf filter elements

| Versis model | Filter Area [m2] | Cake volume [dm3] | Filter leaves | Filter volume [dm3] | Leaf spacing [mm] | Floor space [mm x mm] | Height [mm] | Weight [kg] |

|---|---|---|---|---|---|---|---|---|

| 800-12/1500 | 12 | 270 | 7 | 1050 | 75 | 1945 x1830 | 3980 | 810 |

| 800-14/1500 | 14 | 310 | 9 | 1050 | 75 | 1945 x1830 | 3980 | 810 |

| 1000-19/1500 | 19 | 410 | 8 | 1690 | 75 | 2360 x 1600 | 4085 | 1190 |

| 1000-22/1500 | 22 | 490 | 10 | 1690 | 75 | 2360 x 1600 | 4085 | 1190 |

| 1000-24/1500 | 24 | 530 | 12 | 1690 | 75 | 2360 x 1600 | 4085 | 1190 |

| 1200-27/1500 | 27 | 590 | 10 | 2520 | 75 | 2720 x 1790 | 4255 | 1525 |

| 1200-31/1500 | 31 | 680 | 12 | 2520 | 75 | 2720 x 1790 | 4255 | 1525 |

| 1200-34/1500 | 34 | 750 | 14 | 2520 | 75 | 2720 x 1790 | 4255 | 1525 |

| 1200-37/1810 | 37 | 810 | 12 | 2855 | 75 | 2720 x1790 | 4855 | 1645 |

| 1200-40/1810 | 40 | 680 | 14 | 2855 | 75 | 2720 x1790 | 4855 | 1645 |

| 1400-45/1500 | 45 | 990 | 15 | 3540 | 75 | 3100 x 2080 | 4380 | 2125 |

| 1400-48/1500 | 48 | 1050 | 17 | 3540 | 75 | 3100 x 2080 | 4380 | 2125 |

| 1400-54/1810 | 54 | 1180 | 15 | 3990 | 75 | 3100 x 2080 | 4990 | 2275 |

| 1400-57/1810 | 57 | 1250 | 17 | 3990 | 75 | 3100 x 2080 | 4990 | 2275 |

| 1600-61/1810 | 61 | 1330 | 14 | 5440 | 75 | 3100 x 2080 | 5195 | 2825 |

| 1600-67/1810 | 67 | 1470 | 16 | 5440 | 75 | 3100 x 2080 | 5195 | 2825 |

| 1600-72/1810 | 72 | 1590 | 18 | 5440 | 75 | 3100 x 2080 | 5195 | 2825 |

| 1800/80/1810 | 80 | 1750 | 16 | 7115 | 75 | 4300 x 2710 | 5365 | 3525 |

| 1800-86/1810 | 86 | 1900 | 18 | 7115 | 75 | 4300 x 2710 | 5365 | 3525 |

| 1800-92/1810 | 92 | 2030 | 20 | 7115 | 75 | 4300 x 2710 | 5365 | 3525 |

| 1800-95/1810 | 95 | 2100 | 21 | 7115 | 75 | 4300 x 2710 | 5365 | 3525 |

| 2000-99/1810 | 99 | 2180 | 18 | 9475 | 75 | 4500 x 2350 | 5570 | 4900 |

| 2000-107/1810 | 107 | 2350 | 20 | 9475 | 75 | 4500 x 2350 | 5570 | 4900 |

| 2000-113/1810 | 113 | 2490 | 22 | 9475 | 75 | 4500 x 2350 | 5570 | 4900 |

| 2000-118/1810 | 118 | 2580 | 24 | 9475 | 75 | 4500 x 2350 | 5570 | 4900 |